Blown Film Bubble Cage/Basket

Categories : Blown Film Extruder Parts

Blown Film Extrusion Machine is a process that extrudes the molten polymer through Blown Film Die Head to process the plastic film. If the bubble tube is unstable when it first comes out from the Die Head, it needs a support to maintain its stability to prevent it from transforming. Therefore, Blown Film Bubble Cage / Basket play important characters here to stabilize and reinforce the blown film bubble tube while blowing. As the cooling system runs well around the circumference of the bubble tube, the Bubble Cage / Basket maintains the stability of the bubble tube over Die Head and Air Ring. It prevents the bubble tube from losing stability and offers higher quality of film which shows the importance of Bubble Cage / Basket. HSIN LONG

Bubble Cage by Motor Control

Categories : Blown Film Extruder Parts

Blown Film Extrusion Machine is a process that extrudes the molten polymer through Blown Film Die Head to process the plastic film. If the bubble tube is unstable when it first comes out from the Die Head, it needs a support to maintain its stability to prevent it from transforming. Therefore, Bubble Cage by Motor Control play important characters here to stabilize and reinforce the blown film bubble tube while blowing. As the cooling system runs well around the circumference of the bubble tube, the Bubble Cage by Motor Control maintains the stability of the bubble tube over Die Head and Air Ring. It prevents the bubble tube from losing stability and offers higher quality of film which shows the importance of Bubble Cage by Motor Control. HSIN LONG

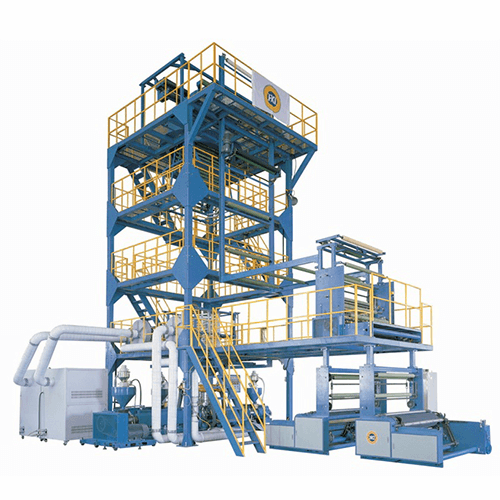

A/B/C BFS Series Co-Extrusion Blown Film Line

Categories : Blown Film Extruders

FKI offers one of the most advanced and adaptable blown film lines for various applications, such as shopping bags, vest bags, garbage bags, agricultural film, construction film, packaging film and lamination film, etc. The workable materials that can be used are such as LDPE , LLDPE, MLLDPE, and HDPE. The film production range is from 200mmto 7 meters in tubular width, and the production output rate is from40kg/hr to800kg/hr. Based on 30 years of experience, FKI is capable of offering blown film lines with reliability and versatility to meet different requirements from mono layer, double color, double layer, and three layer to four color designs.

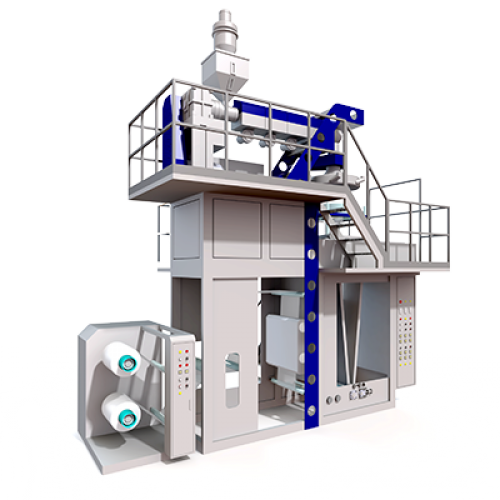

PP Blown Film Line(JC-PB Series)

Categories : Blown Film Extruders

JC-PB Series Blown Film Extrusion Line is downward inflation water cooling line for production of high clarity PP film.

Mini HDPE/LDPE Blown Film Line (JC-HM Series)

Categories : Blown Film Extruders

JC-HM Series Mini HDPE/LDPE Blown Film Extrusion Line is the most cost-effective solution for high speed monolayer film production. Emphasize for high speed monolayer film production. Emphasize on reliability, easy operation, flexibility and swift product change.

ABA Blown Film Machine (JC-ABA Series)

Categories : Co-Extrusion Blown Film Machines

JC-ABA Series - 3 layer Co-Extrusion Blown Film is the ultimate solution producing high quality film at lower production cost. The ABA 3 layer co-extrusion line consist two high performance extruders with a 3 layer ABA co-extrusion die head. The outer layer is dominantly with virgin materials, and the core layer with large percentage of CaCo3 or in-house recycled pellets material. Further the ABA 3 layer blown film structure also persist higher strength characteristic than conventional monolayer film, which overall gives an advantage to the competitive market.